In the vast system of road transportation, trucks are undoubtedly the core force of freight transportation. They carry tons of goods and shuttle between roads in various road conditions. And among the many parts that ensure the efficient and safe transportation of trucks, shock absorbers play a crucial role.

Working principle of truck shock absorber

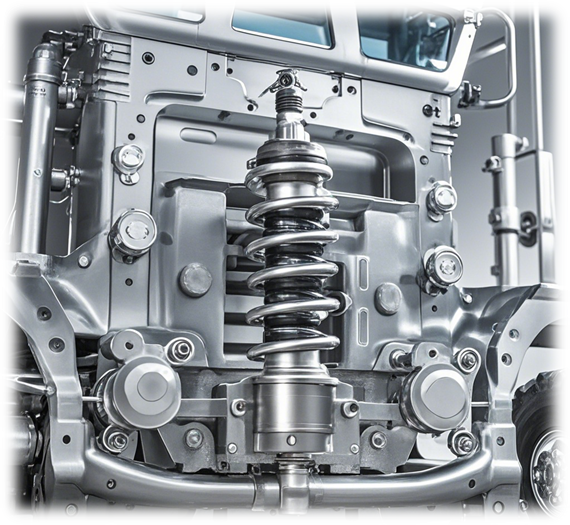

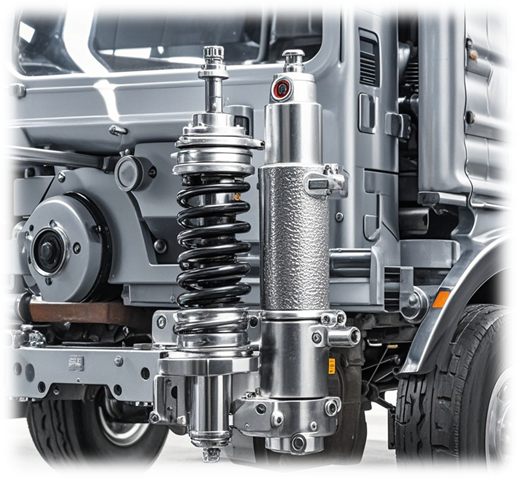

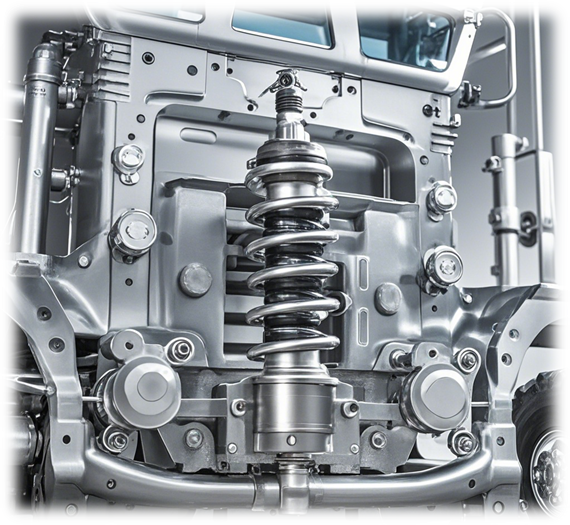

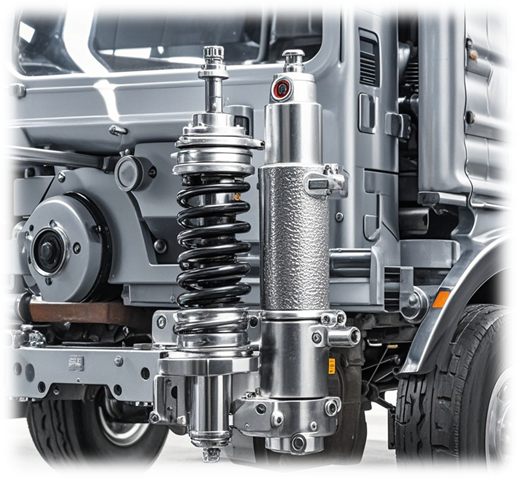

Truck shock absorbers mainly work based on the principle of damping. When the truck is driving on the road, the wheels vibrate up and down due to the uneven road surface. The shock absorber is filled with oil or gas, which is consumed by the reciprocating motion of the piston in the cylinder. For example, when the piston in the hydraulic shock absorber moves up and down, it forces the oil through the narrow hole. This throttling effect converts the mechanical energy of the vibration into heat energy, thereby reducing the vibration amplitude of the vehicle. For some high-end shock absorbers, special valve systems are also equipped, which can automatically adjust the flow resistance of the oil according to the intensity and frequency of the vibration, and control the shock absorption effect more precisely.

The important influence of shock absorbers on truck performance

Enhance driving comfort

For truck drivers who drive long distances, the quality of the shock absorber directly determines their driving experience. On bumpy roads, if there is no good shock absorption, the driver will endure severe vibrations for a long time, which will not only cause physical fatigue, but also affect driving concentration and increase the risk of traffic accidents. High-quality shock absorbers can effectively filter out most of the road bumps, keeping the cab relatively stable, allowing drivers to complete long-distance transportation tasks more comfortably.

Protect the safety of goods

Trucks transport a wide variety of goods with different values. During transportation, excessive vibration may cause damage to the goods. For example, when transporting fragile goods, precision instruments and other goods, a good shock absorption system can minimize the impact force on the goods and ensure that the goods arrive at the destination intact. Even when transporting ordinary goods, the stable driving state can avoid the displacement and collision of the goods due to shaking, and ensure the integrity and safety of the goods.

Extend the lifespan of vehicles

The shock absorber also has a protective effect on the overall structure of the truck. Continuous strong vibration will accelerate the wear of vehicle parts, such as tires, suspension systems, frames, etc. Effective shock absorption can reduce the impact force on these parts and reduce the wear rate, thereby prolonging the service life of the vehicle, reducing maintenance costs and the frequency of replacement parts, and saving a lot of operating costs for logistics enterprises.

The characteristics of different types of truck shock absorbers

Leaf spring shock absorber

This is a traditional and widely used shock absorption method. It uses the elastic deformation of the leaf spring to absorb vibration. It has a simple structure, low cost and strong bearing capacity, making it especially suitable for heavy-duty trucks. However, its shock absorption effect is relatively limited, and the comfort is poor. In the face of complex road conditions, the vibration filtration is not fine enough.

Air spring shock absorber

The air spring shock absorber uses compressed air as an elastic medium. It can automatically adjust the height and hardness according to the load of the vehicle, providing a smoother driving performance. It performs well in terms of comfort and can adapt to a variety of road conditions. However, it is more expensive and requires strict sealing. Once air leakage problems occur, it will affect its normal use.

hydraulic shock absorber

Hydraulic shock absorbers, as mentioned earlier, absorb shock through the damping effect of hydraulic oil. It has a good shock absorption effect and can effectively suppress the vibration and bounce of the vehicle. Moreover, the technology of hydraulic shock absorbers is relatively mature and highly reliable. But after long-term use, problems such as oil leakage may occur, and regular inspection and maintenance are required.

The development trend of truck shock absorbers

With the continuous advancement of science and technology, truck shock absorbers are also developing in the direction of intelligence and high performance. Future shock absorbers will more accurately perceive road conditions and vehicle states, and realize real-time automatic adjustment through integration with the vehicle's electronic control system. At the same time, the application of new materials is expected to further improve the performance and durability of shock absorbers, reduce weight, and provide more powerful guarantees for the efficiency and safety of truck transportation. In today's transportation industry increasingly pursues efficiency, safety and comfort, the continuous innovation and development of truck shock absorbers will surely become an important force to promote the progress of the entire industry.