In the torrent of highway transportation, trucks are like resolute giants, shouldering the heavy responsibility of transporting materials and connecting industrial chains, speeding between urban streets and vast wilderness. Beneath this seemingly rugged behemoth lies a precision part that is often overlooked but extremely important - the truck shock absorber. It is like a loyal guard who silently protects and single-handedly lays a solid foundation for the smooth driving, comfortable ride and operational safety of the vehicle.

Extraordinary Structure: A Mechanical Masterpiece of Rigidity and Flexibility

The design of truck shock absorbers is like a delicate "ballet" of mechanical engineering, integrating the perfect balance of strength and elasticity. When examining its appearance, the shell is mostly made of high-strength alloy steel. After going through complex processes such as forging, polishing and rust prevention treatment, it forms a tough "armor" that is sufficient to withstand the impacts of flying sand and stones, rain erosion and frequent external "beatings" under complex road conditions, ensuring that the internal precision structure remains unscathed.

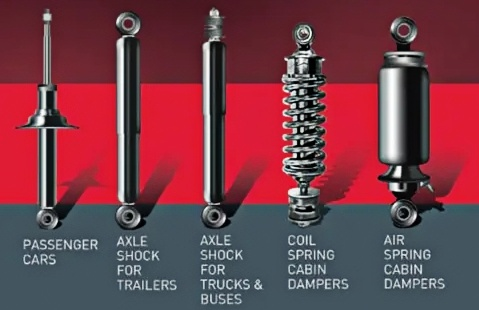

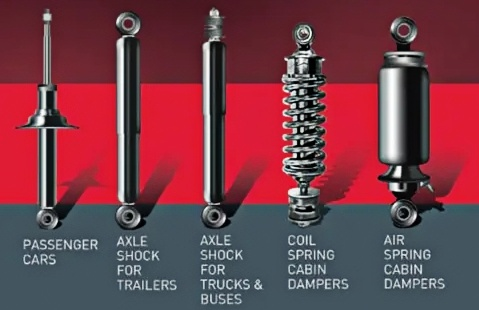

Looking deeper inside, the core components perform their respective duties while coordinating with each other. The rubber airbag, as the "buffer pioneer", is made of a combination of high-quality natural rubber and highly elastic synthetic rubber. It has astonishing flexibility and resilience. When the vehicle passes over potholes and bumps, it is like a highly elastic "sponge pillow", instantly deforming to absorb impact energy and then quickly rebounding and resetting, continuously the "onslaught" of vibrations. Working side by side with it is the coil spring, which is precisely wound from high-strength spring steel wire. According to the differences in truck tonnage and usage, the number of turns, density and diameter specifications are carefully designed to provide a stable upward supporting force when bearing the heavy pressure of the vehicle body, just like an "elastic pillar". Combined with the rubber airbag in a dynamic and static way, every bump can be cleverly tamed.

Outstanding Efficiency: Driving the Upgrade of Transportation Quality

Outstanding Efficiency: Driving the Upgrade of Transportation Quality

When it comes to driving texture, the shock absorber can be called the "magician" of truck driving experience. When cruising on a flat highway, it turns into a fine "sieve", quietly filtering out the high-frequency vibrations derived from the subtle textures and connection gaps of the road surface. The steering wheel in the cab is firmly held in hand, and the seat is as stable as a rock. Drivers are free from the annoyance of continuous shaking. Even on long-distance runs, they can be refreshed and focused on the road conditions, reducing the hidden danger of fatigue driving. When facing rugged mountain roads and unpaved off-road sections, it transforms into a "balance helmsman", fully suppressing the violent shaking and tilting of the vehicle body, ensuring a stable vehicle center of gravity. The tires cling to the ground like geckos. Even when fully loaded with goods and climbing slopes and making turns, it can be easily controlled, greatly enhancing driving safety.

Focusing on the transportation benefit level, the contribution of shock absorbers cannot be underestimated. With excellent cushioning and shock absorption, the goods in the carriage are like being in a "safety cabin". Precision instruments, fragile goods, fresh supplies and other items are protected from violent impacts, and the damage rate drops sharply. Avoiding replenishment due to cargo damage during transportation and ensuring a "green light" for logistics timeliness all the way. Stable driving posture can also extend the "service life" of related parts such as tires and suspensions, reduce abnormal wear and failure frequency, and reduce maintenance costs, helping trucks maintain efficient attendance and gallop on the profit "track" year after year.

Innovation Wave: Embarking on the Future Technological Journey

Innovation Wave: Embarking on the Future Technological Journey

Today, the technological wave is surging. The field of truck shock absorbers is also striving to be at the forefront of innovation. In the field of materials science, new materials such as smart memory alloys and adaptive rubbers are emerging. They can intelligently adjust their elastic modulus and damping coefficient according to changes in temperature, vibration frequency and load pressure. No matter in severe cold or sweltering heat, light or heavy loads, they can "adapt" and output the optimal shock absorption effect. In terms of design and research and development, relying on big data analysis and computer simulation technology, massive amounts of data on road conditions, driving habits and vehicle operating conditions are collected for modeling and optimization to customize "exclusive shock absorption solutions" for trucks of various . What is even more remarkable is that it is deeply integrated with autonomous driving and vehicle networking systems and transforms into a "smart terminal", sensing road undulations and abnormal vehicle conditions in real time, remotely transmitting data and automatically adjusting shock absorption parameters. Working together with the whole vehicle intelligent system to create a "smart truck" and reshape the future transportation pattern.

Although the truck shock absorber is hidden in the dark of the vehicle chassis, with its persistent perseverance and extraordinary performance, it props up the "stable sky" of truck transportation and becomes an indispensable "behind-the-scenes hero" on the highway, continuously empowering modern logistics to move forward efficiently and steadily.